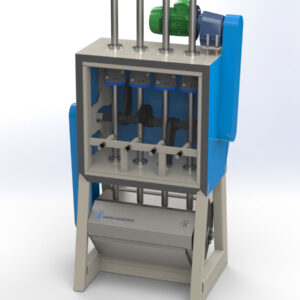

Hammer Mill

Features & Benefits:

- 100% of screen utilized for maximum efficiency

- A variety of hammer sizes, patterns, and screen openings available to tailor parameters for each application

- Large access doors make cleaning and maintenance simple and quick

- Screw feeding shaft is available to move material

- Easy to replace the parts according to the product

- Used of high precision components

- Granulating of almost any material

Hammer mills are the premier choice for applications requiring high capacities, operational efficiency, and uniform particle size distributions. Hammer mill is among the oldest, commonly used for pulverizing. Machine consisting of a series of beater (usually four or more) hinged on a focal shaft and encased securely within a rigid metal case .hammer mills are equipped with auger screw to remove all the material in the blower pipeline which help in cleaning and reduce low wastage of the product. Hammer mill is covered with the mesh to filter all the material to required size. Hammer mill is having 2 motor which controls beater shaft and auger screw and blower. Hammer mill machine is made of high precision material to reduce maintains. The machine is designed for continuous heavy duty operation.